In Brazil ammonium nitrate, the cause of the explosion in Beirut, represents 0.4% of total imports

Aug, 11, 2020 Posted by datamarnewsWeek 202033

The explosion at the Port of Beirut, Lebanon, on August 4th, probably caused due to the incorrect storage of ammonium nitrate, sparked concern about the conditions of transportation and storage of the product – used in the manufacture of fertilizers – in Brazil. Ammonium nitrate is the raw material for a common fertilizer in Brazilian agriculture, in use for at least 50 years, especially in the production of sugar cane, fruits and vegetables. Much of this raw material used in Brazil is imported from Estonia – about 80%, according to DataLiner.

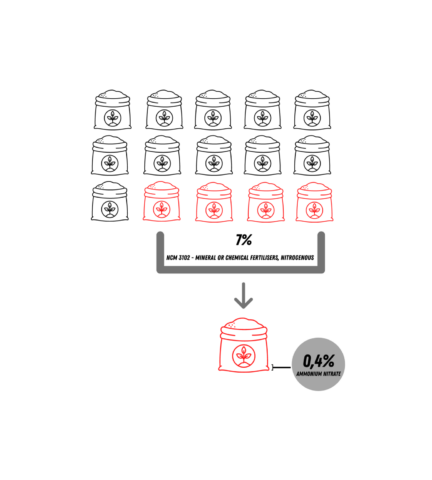

Data from the DataLiner indicates that in the first half of 2020, fertilizers corresponded to 24.1% of Brazilian imports. Of these, the 3102 NCM group, which includes ammonium nitrate, corresponds to about 7% of imports. Ammonium nitrate represented 0.4% of the total imported by Brazil in the first half of 2020.

Source: DataLiner

Most of the ammonium nitrate imported by Brazil arrives in bulk (98%). One to three monthly vessel calls is loaded with the product. Each vessel call represents about six times the volume of cargo that caused the explosion in Lebanon.

Percentage of ammonium nitrate imported in containers vs. in bulk

Source: DataLiner

Main Brazilian ports receiving ammonium nitrate:

Source: DataLiner

(To request a DataLiner demo click here)

Despite the large volume of imported ammonium nitrate, the risk of explosions is not as common. Ammonium nitrate, in small quantities and well stored, is not dangerous. It can cause a big explosion when exposed to high temperatures. In Beirut, for example, the nitrate was kept in a warehouse for six years, without the necessary security. In Brazil, the product is inspected by the Controlled Products Inspection Directorate (DFPC), linked to the Brazilian Army.

Care in ports

Responsible for receiving the largest volume of ammonium nitrate in Brazil, the Port of Paranaguá states that the product represents only 3.5% of the total imported fertilizers received at the site. “We have never had any problems related to this substance. The port authority, as well as the terminals, operators, and warehouses, operate with the appropriate updated security plans ”, says the CEO of Portos do Paraná, Luiz Fernando Garcia. “Specifically in relation to ammonium nitrate, those who work with the product follow a strict inspection and accountability routine imposed by the Controlled Products Inspection Department (DFPC)”.

Garcia also recalls that the labor used, both in the port area and in terminals and warehouses, in the operations of import bulk is extremely qualified. “The companies, as well as the Management Body of Outsourced Labour (OGMO), always offer courses and training”, he says.

Four companies operate the product in the ports of Paraná. According to the Operations Directorate, there are 11 warehouses accredited (by the port authority and the Army) to receive ammonium nitrate. “It is a product controlled by the Army, which inspects the warehouses, and only with its approval, do we accredit the warehouses to receive the product”, says the director of Operations for Portos do Paraná, Luiz Teixeira da Silva Júnior.

According to fertilizer operators in the Port of Paranaguá, to work with ammonium nitrate, companies must apply to DFPC for a special registration certificate (CR). In order to provide it, the institution guides adjustments ranging from the construction of warehouses, product security (to prevent diversion or theft), storage to staff training.

There are countless items checked before approving the concession. Even with the registration of each import, the army is notified and issues a specific license, after assessing the documentary situation. Even before the ship is docked, the army must be notified of the location where the incoming cargo will be taken and stored. Even for a short journey, from the pier to the warehouse, the truck that transports the product must also be certified. At the Port of Paranaguá, these vehicles and their drivers are specifically trained for this transportation and receive an identification stamp from the army. At warehouses, the product is accommodated between concrete walls, in boxes lit with cold lamps, duly identified, with access control, security warnings and properly trained personnel.

The Santos Port Authority (SPA) also ensures that all security measures are taken care of. “The handling takes place at the Guarujá Maritime Terminal (Termag), located on the left bank of the port. The product stored in this terminal is Class 5 ammonium nitrate (oxidizer), intended for agricultural use, with strict monitoring of temperature and humidity, rotation of stored volumes, and mixed with limestone, to give greater stability to the product. It is not stored for long periods, it is basically a direct transfer operation from ships to trucks ”, said the SPA in a note.

“What is known so far about the accident in Beirut is that the cargo would be stored without complying with safety standards, with no information on what actually caused the accident in question. At Santos, the SPA emphasizes that safety is a priority, thus, all operational procedures are carefully followed by those responsible for operations and accompanied by intensive inspection, providing total security to the population ”, added the port authority.

-

Ports and Terminals

Aug, 22, 2022

0

Itajaí, Navegantes see combined throughput of more than 1.4 million tonnes in July

-

Ports and Terminals

Feb, 13, 2023

0

Ponta do Felix port to carry out wheat transport via cabotage

-

Ports and Terminals

Jul, 27, 2021

0

Chittagong port yards face severe box congestions in lockdown

-

Economy

Mar, 02, 2022

0

Exports from Brazil to Arab market up 55%